South African National Pavilion in Hall 14 – Stand D 48

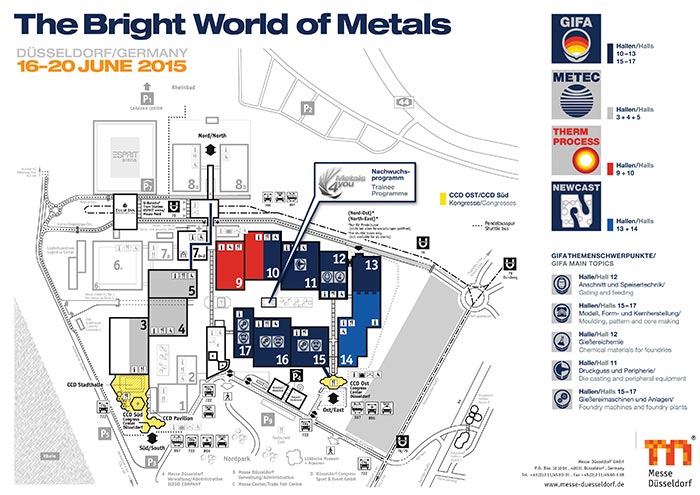

From 16 June to 20 June 2015, the Düsseldorf Trade Fair Center will play host to the trade fair quartet comprising GIFA 2015, International Foundry Trade Fair with WFO Technical Forum, METEC 2015, 9th International Exhibition for Metallurgical Technology with Congress, THERMPROCESS 2015, 11th International Trade Fair and Symposium for Thermic Production Processes, and NEWCAST 2015, the 4th International Trade Fair for Cast Products.

It is very encouraging that a number of South African companies will again be participating this year both on the South African National Pavilion in Hall 14 – Stand D 48, and as individual companies such as Itshe Resources (Pty) Ltd who will have their own stand in Hall 13 Stand C61.

Full details of the companies participating are listed below.

South African National Pavilion in Hall 14 Stand D48

Aluminium Federation of South Africa (AFSA)

The Aluminium Federation of South Africa is the voice of, and the gateway to, the South African aluminium industry. AFSA’s members are companies operating in any sector of the industry that covers the full range of activities from primary aluminium production, through secondary smelting, semi-conversion, casting, fabrication, extrusion, distribution and surface finishing.

The South African aluminium industry is focused on:

- Growing and developing a co-operative and outward orientated industry;

- Being well promoted both in terms of the material (aluminium) and the industry; and

- Adding downstream value.

The purpose of AFSA is to promote the use of aluminium and the Southern African aluminium industry, both regionally and internationally and in doing so, to represent and defend the interests of its members.

The key roles of the Federation, and the sector Associations acting under the aegis of AFSA, are to:

- Facilitate, assist and support growth initiatives (in an enabling climate for all stakeholders) both regionally and internationally.

- Promote the awareness of aluminium, its application and promote the aluminium industry with input from the industry role players.

- Assist and participate in knowledge diffusion and transfer:

– generic technology

– product development

– information and statistics

Via working linkages / synergies (often working with champions). - Facilitate and advise in areas of education and training at appropriate levels.

- Make mandated representations for the industry on relevant matters and especially key national issues.

Sector Associations – the corner stones of the Federation

AFSA’s approximately 150 members are grouped into one or more industry sector Associations. Association members meet on a regular basis to discuss areas of common interest, within the limitations imposed by the Competitions Act. Typical programs include market research, sector promotion, marketing and education, workshops, seminars, standards’ development and government liaison regarding trade practices, duties and incentives. Each Association has their own budget and appoints a chairman who represents that Association on the AFSA Executive Committee.

There are currently four active sector Associations in AFSA and these are:

• ACA – Aluminium Casters Association

• AFA – Aluminium Fabricators Association

• ASPA – Aluminium Sheet Products Association

• ASFA – Aluminium Surface Finishers Association

AFSA has a well defined marketing strategy, the main focus of which covers generic promotion of aluminium – alongside co-ordinating the promotional activities of the various Associations, plus the development of commercial material such as the Industry Directory, and training and education publications.

Mark Krieg and Rentia Malan will be on the stand.

For further details contact The Aluminium Federation of South Africa on TEL: 011 453 3339, email: afsa@afsa.org.za or visit www.afsa.org.za

Factocode (Pty) Ltd t/a Microfinish

The Pinetown, KwaZulu Natal based firm is an automotive component manufacturer in the niche market of valve guides and valve seat inserts to OE and aftermarket customers. The company has two distinct operating divisions, the Factocode Foundry, which manufactures castings and the manufacturing plant, where the castings are machined into the finished product.

For further details TEL: 031 737 3300 or visit www.microfinish.co.za

Fochem International

Fochem International offers application-specific products for many different processes of the metal working industry and other related industries.

Fochem’s comprehensive portfolio ranges from release agents, specialised lubricants, and coatings to tailor made speciality products. The company’s focus is on innovative solutions with added value for their customers. In order to accomplish this target, Fochem often work in close cooperation with their international partners and their customers.

Fochem take great pride in Research & Development. New manufacturing technologies are constantly developed and their existing processes are frequently improved.

Fochem International has an integrated value chain from crude graphite powders to finished compounds. The company only processes high purity raw materials that are environmentally friendly. Fochem’s state-of-the-art production site south of Johannesburg guarantees a high quality consistency of products.

Fochem International is proud to have one of the world’s most advanced high-tech, safe and eco-friendly production facilities of its kind. The essential production stations are fully automatic and are systematically controlled.

Moreover, the company is involved in social programmes, which focus on education, training and development and support of their workers.

Products

Fochem’s product portfolio comprises several graphite-based beads and white beads, available in different sizes and solid content, graphite powders, high pressure die-casting lubricants and release agents, coatings for gravity and low pressure die-casting, forging compounds, extrusion compounds, micronised graphites, dry lubricants for the extrusion of aluminium, brass and copper and coatings for primary refineries, the electronics industry, high tension cables and many other industries.

Worldwide

Fochem operates in close cooperation with their clients through their international agents network. It is the company’s aim to reach as many customers as possible.

Axel Bastian and Julia Bastian, as well as Anton Mostert and Lerato Hlongwane will be present on the stand.

For further details contact Fochem International on TEL: 011 903 9720 or visit www.fochem-international.com

Lauds Foundry Equipment

Lauds Foundry Equipment designs, manufactures and supplies original equipment for the foundry industry in the EU, Turkey, South Africa and neighbouring countries.

Lauds Foundry Equipment has recently expanded its existing facility from 2 000m² to 4 000m². This has enabled the company to expand their manufacturing facility to handle much larger projects, and at the same time separate the facility into four sectors, namely:

- Fabrication

- Machine shop

- Electrical

- Stores

In doing this Lauds’ have created a clean work-flow, enhancing the company’s ability to manage quality and deliverables much more efficiently.

Before dispatch equipment is assembled and tested. This avoids delays with commissioning and ensures that all equipment is quality assured according to client specification, upon delivery at client site.

Lauds’ services extend to turnkey projects with the ability to deliver a total solution for complete foundry installations including environmental assessments and obtaining operating licenses.

Lauds are proud to announce that 90% of their clients purchasing mixers have invested in the company’s temperature sensitive autoblend and auto calibration systems, and are seeing the results in the reduction of wastage and elimination of human error. In a skills deficient market Lauds accommodate the semi-skilled operators with their state of the art automation.

Lauds manufactures a full range of no bake equipment with control systems that give clients the ability to provide critical information such as costing, material use, temperature ranges and many other additional features.

Global partners

Lauds continues to have mutually beneficial arrangements with its global partners. These include Pourtech AB (Germany) a manufacturer of automated pouring solutions, Siapro (Slovenia) a manufacturer of shotblast equipment, Indemak (Turkey) a manufacturer of furnaces, Adjatech (Poland), who are an agent for the company and SLT | Modern Foundry Technologies, a distributor in Russia.

Lauds will be exhibiting a Lauds 6TPH portable chromite mixer, a Lauds 3TPH compact reclamation plant and a Lauds 6TPH pressure vessel.

Kevin van Niekerk, CJ Lindeque and Stephen O’Reilly will be present on the stand.

For further details contact Lauds Foundry Equipment on Tel: 011 824 1238 or visit www.laudsfe.com

Lauds portable chromite mixer

Lauds screw articulate mixer

Lauds compact reclaimer

Metallurgical Testing Labs

Metallurgical Testing Labs (also known as MTL) is a fully SANAS Accredited 17025:2005 testing facility which was established in 2012. MTL carries out testing for a number of industries including, but not limited to, power and petrochemical, mining and construction, foundry and automotive.

MTL runs a paperless LIMS system, which is integrated into its testing equipment which significantly reduces the potential for operator error. MTL has made significant investments to ensure that it is able to operate at 100% capacity even in the event of load shedding.

MTL’s purpose is to provide valuable information pertaining to a material’s/component’s quality as it pertains to the “fit for use concept”.

MTL works closely with its customers to ensure that their needs and expectations are met.

As a fully independent testing facility, which is run and managed by its owner Graham Knight, MTL prides itself on being flexible when it comes to being able to cater to the needs of its client base.

For more information regarding MTL’s services TEL: 011 452 4541, email graham@mtlabs.co.za or technical@mtlabs.co.za or visit www.mtlabs.co.za or follow them on the Facebook or LinkedIn Platforms.

Procon Africa

Consultants in construction, structural and mechanical services for the mining and metals industries.

Rand York Minerals

Rand York Minerals are suppliers of foundry chromite sand worldwide. Zelda du Preez and Michelle de Bruyn will be at their stand.

Scaw Metals Group

The Scaw Metals Group is a proudly South African integrated steel manufacturer with global reach through established operations in South Africa and Australia, and a presence in Ghana, Namibia, Zimbabwe and Zambia. The Company has its major operations in Germiston, Gauteng.

Cast Products is one of the oldest and most important manufacturing operations in the Scaw Group. The Scaw foundries employ approximately 1,800 people across its four foundries and its wheel plant. Each plant specializes in specific products in terms of process control and plant optimization, resulting in the best quality at the lowest cost of manufacture. Three large on-site machine shops, with extensive machining capabilities, allow Scaw to supply finished products which are ready to install.

Scaw’s Germiston Foundry in South Africa is one of the largest foundries in the southern hemisphere and produces castings in finished weights up to 30 tons. It is a leading supplier of single-piece, thin-walled locomotive and passenger frames, freight car components and high integrity cast steel railway wheels. The foundry holds the American Association of Railroads’ approval for the manufacture of freight-car side frames, bolsters and cast-steel wheels.

Other products include large gear segments, high-carbon, high-chromium, abrasion resisting coal grinding elements for coal-fired power stations, high-chromium iron mill liners and impact crushing parts, stainless-steel coiler drums, and a range of slag ladles for the metal processing industry. Arc furnace melting units and a 25 ton capacity ladle vacuum degassing unit serve the foundry where steels can be produced with lower sulphur, nitrogen, oxygen and hydrogen contents, particularly necessary for the manufacture of high strength, low-alloy steels.

Scaw’s other foundry operations (Standard, Boksburg, and Eclipse East) produce a vast range of cast wear parts from a variety of materials that can be custom designed according to individual customer specifications. The product range includes mill liners, cone and gyratory crusher wear parts, jaw crusher wear parts, impact crusher wear parts, dragline and shovel parts, shredder wear parts, railway parts and mining spares.

International standards

Scaw is an ISO 9000-series accredited organization manufacturing products to meet the requirements of the appropriate international certification authorities. Scaw’s safety, health and environmental management systems are aligned with the international ISO 14001 and OSHAS 18001 standards.

Laurence Erasmus, Jaco van der Merwe and Duan Maritz will man the stand.

For further details contact Scaw Metals Group (Scaw), TEL: 011 621 1555, email: laurence.erasmus@scaw.co.za or visit www.scaw.co.za

South African Institute of Foundrymen

The South African Institute of Foundrymen (SAIF) is a non-profit company that has been active within South Africa, initially as a branch of the Institute of British Foundrymen from1939 to 1964, and subsequently as an independent institute.

Over the years, the Institute has been a leader in technology transfer and technical education in the metal casting sector. Skills and apprentice training in the Gauteng and other regions is being presented at various venues and a new training centre, the Gauteng Foundry Training Centre, was launched in 2013 for the training of patternmakers, moulders and melters. More than twenty apprentices are currently receiving training at the centre.

Aims of the SAIF

The main aim of the SAIF is to promote and develop within Southern Africa the science, technology and application of metal casting and foundry work for individuals and involved industries through:

• Appropriate skills development, training and education

• Dissemination of relevant information and knowledge

• Building cooperation and fellowship within the industry and institutional partners

• Developing and promoting career awareness to attract talented technical and business leaders for the future

The SAIF also represents the metal casting industry in common challenges and initiatives with government, municipal and other local authorities, state owned organisations, educational authorities and the standards authorities on all matters within its mandate.

In partnership with the tertiary and other institutions, other associations and the National Foundry Technology Network (NFTN) the SAIF is active in assisting foundries to become more technologically aware and globally competitive. Projects aimed at energy saving, recycling, simulation modelling and lean manufacturing are in progress. Joint projects are undertaken with several government agencies to further the scope and opportunities to grow the foundry industry and create employment in the country.

Benefits offered to members of the SAIF

Education and Training: Realising the need for both operator / artisan and technical training for the industry, the Institute is committed to on-going development of knowledge and skills courses and seminars in conjunction with both local and overseas institutes. Foundry technical courses are run in conjunction with the University of Johannesburg on a regular basis. In addition to the skills development programme, customised, in house courses or courses for which there is a popular demand and other workshops are presented regularly to industry members assisted by funding provided by the NFTN.

Trends and technology: You or your company can benefit by being kept up to date and familiar with local and international technology and trends relating to foundry activities.

Castings SA: You will receive a free copy of Castings SA, an alternate monthly publication which reaches decision makers at all levels and sectors of the industry. The publication covers topical local and international news and technology and applications in foundry practice, as well as news of the SAIF activities.

Technical papers: Members and their guests are invited to technical presentations on a monthly basis and have access to other meetings and networking resources. Members will also be eligible to join technical committees and influence technology transfer to industry.

Newsletters: Members will receive all SAIF publications and newsletters.

Works visits: Several times a year, the Institute organises visits to a foundry or allied interest works.

Annual awards dinner: Awards presented at this function include the Morganite Medal for best presentation paper of the year by an SAIF member, Non-members’ diplomas for best presentation paper by non-members, Past President’s certificate and plaque and Honorary Membership. Student awards are made to outstanding learners at the Universities and successful learners attending the SAIF technology courses.

Literature: The SAIF library, which forms a part of the University of Johannesburg library, is open to any member, making both international publications and reference works available. In addition specific technical information on foundry topics can be made available electronically. Industry knowledge in the form of technical books, research reports and transactions will be available to members at discounted prices.

Seminars: Are organised in conjunction with local or international partners as they occur. These are one to three day seminars which cover foundry and related subjects.

Company members: Company profiles may be placed on the website.

John Davies will attend. For further details contact the South African Institute of Foundrymen on TEL: Secretary: 011 559 6455, e-mail: mbiljon@uj.ac.za or TEL: CEO: 011 559 6468, jdavies@uj.ac.za or visit www.foundries.org.za

Thermopower Furnaces S.A.

Thermopower Furnaces (Pty) Ltd specialises in innovative furnace design and manufacturing.

Established in 1968, Thermopower develops, designs, manufactures, installs and commissions specialised thermal equipment. Covering a full range of fields and industries, Thermopower’s heat treatment furnaces, melting and holding furnaces, drying furnaces, processing and calcining furnaces operate all over the world.

Thermopower Furnaces manufactures to specification, offering the steel industry tailored thermal processing solutions. In addition Thermopower offers comprehensive R&D services whereby the company’s experienced team carry out thermal process development for clients.

Thermopower Furnaces builds equipment for a wide range of industries, including mineral beneficiation, composites manufacture, steel manufacture, ceramics manufacture and hazardous waste destruction.

Experience in the steel industry includes furnaces for annealing, normalising, aging/ precipitation hardening, quenching, tempering, melting and holding, forging, wax burnout, mould curing and firing of technical ceramics for foundry applications.

The exhibition stand will be manned by William Oldnall and Brendyn Fahy.

For further details contact Thermopower Furnaces S.A. (Pty) Ltd on TEL: 011 316 2184, email: sales@thermopower.co.za or visit www.thermopower.co.za

Thos Begbie & Company

Thos Begbie was established in Johannesburg in 1887 as a Foundry and General Engineering business and in 1907 relocated to Middelburg, Mpumalanga. Today Thos Begbie is one of the few fully integrated foundry and general engineering operations in the country, supplying all major sectors of industry.

Thos Begbie services include:

Pyrometallurgical component manufacturer

This division is equipped to produce a comprehensive range of copper and copper alloy castings. The annual capacity is in excess of 1100 tons of finished product with a maximum cast mass of 7 000 kg. These products are supplemented by an extensive range of copper based alloy components.

General engineering

The General Engineering Division primarily provides foundries with machining capacity. It includes a CNC machining centre, grinding machines, milling machines, and power saws. They also operate the largest horizontal floor borer and vertical mill in the region, which provides for machining of abnormally sized components. It also provides services to the local mining, power generation, paper processing, steel mills and ferro alloy producers.

Technical services

These include pattern making facilities, a metallurgical analysis laboratory, technical customer liaison and, methoding – a computerised Solstar Solidification Modelling.

Quality assurance

Thos Begbie’s quality management system complies with the requirements of SABS ISO 9002, which was awarded to the company in 1990.

Thos Begbie is a privately owned company.

The exhibition stand will be manned by Eugene Rossouw and Harry Mulller.

For further details contact Thos Begbie on TEL: 013 246 9100, email: harrym@thosbegbie.com or visit www.thosbegbie.com

Hall 13 Stand C 61

Itshe Resources

Itshe Resources (Pty) Ltd was founded in 2006 to market foundry grade chrome sand from South Africa. The company serves the local and global foundry and refractory markets with both wet bulk sand from Richards Bay, and containerised dried and bagged shipments from Durban.

Chrome sands and concentrates are sourced from two major mines, one on the western side and one on the eastern side of the Bushveld mineral complex. Drying facilities are located in Durban for the export containerised markets. Distribution of chrome sand is supported by their warehouses in Johannesburg and Durban and the long-term commitment from the mines to produce quality foundry sands and concentrates for industry.

Itshe Resources also distributes Metallurgical and Refractory grades of chromite ores which are used in the metallurgical, foundry, refractory and pigment applications.

Graham Evans, Brett Proctor and Ernest Mberi will be at GIFA on stand C61 in Hall 13.

For further details contact Itshe Resources (Pty) Ltd on TEL: 011 706 0322,

email info@itsheresources.com or visit www.itsheresources.com

Hall 13 C 20-10

University of Johannesburg, Metal Casting Technology Station

The Metal Casting Technology Station [MCTS] is a technology transfer partner for the metal casting industry, pioneering development through training, research and technology support.

A non-profit initiative funded by the Department of Science and Technology through the Technology Innovation Agency [TIA], the Technology Station operates from the University of Johannesburg in partnership with the Department of Metallurgy in the Research faculty.

The MCTS supports and assists the metal casting industry, foundries, suppliers and related industries to improve the sector’s innovation ability for increased competitiveness and sustainability.

The MCTS’s focus is on research, casting design and simulation, education and training, physical metallurgy, rural and emerging foundries and sand technology.

The core services that he MCTS carries out is CAD design, casting simulation, additive manufacturing, technology demonstration, training, technology development, material testing, metallurgical and failure analysis, moulding systems analysis and troubleshooting, moulding material analysis and development, internship and research.

The UJ-MCTS will be exhibiting on the GIFA –Institutes Stand. The following UJ-MCTS staff members will travel to Düsseldorf: Mr Varachia, Dr Nyembwe, Mr Banganayi, Mr Mageza, Mr Mavhungu, Mrs Driessel and Miss Masutha.

For further details contact The Metal Casting Technology Station on TEL: 011 559 6019 or visit www.metalcasting.co.za

SAIF networking evening at GIFA 2015

The South African Institute of Foundrymen will hold a cocktail evening at the South African National Pavilion in Hall 14 Stand D 48 on Wednesday 17th June 2015, at 17h30. The ‘meet and greet’ function will enable all South Africans attending GIFA 2015 to network with their peers, colleagues and friends from South Africa, as well as VIP guests that will be invited.

If you are attending GIFA 2015 and intend to be part of the networking evening please contact the SAIF offices to confirm your attendance. The contact details are: TEL: Secretary: 011 559 6455, e-mail: mbiljon@uj.ac.za or TEL: CEO: 011 559 6468, jdavies@uj.ac.za

All are welcome but for catering purposes please advise the SAIF.

Additional South African participation at GIFA 2015

Below is a list of companies involved in the metal casting industry in South Africa that will have representation at the exhibition. Listed are the personnel from the company that will be attending and the details of the international companies that they represent, including hall and stand numbers for easy location.

ABP Induction Systems Hall 10 Stand A42

Byron McCall will be on the stand. For further details TEL: 011 623 1814 or visit www.abpinduction.com

Production range includes induction systems for melting, pouring and holding ferrous and non-ferrous metals, heated and unheated pouring furnaces, inductive heating equipment for forming, heat treatment and hardening as well as modern control technology.

Ametex

Andrew McFarlane and Erik Zimmermann will attend. For further details TEL: 083 3061867 or visit www.ametex.co.za

Magma GmbH Hall 12 Stand A20

Magma offers comprehensive solutions for information processing, consultation and planning services. Magma’s product and service portfolio includes modular simulation software as well as engineering services for casting design and optimisation.

For the first time, MAGMA5 Release 5.3 makes virtual experimentation and automatic optimisation on-screen possible. Robust process conditions and optimised solutions for casting layouts and part production can be determined before the first casting is produced. The software is designed to find the best possible set-up for runner dimensions, gate positions and also for both the position and the optimum size of feeders and chills. Foundrymen can use simulations in a virtual proving ground to pursue different quality and cost objectives simultaneously. Since MAGMA5 comprehensively simulates the casting process as well as upstream and downstream processes, these can also be optimised which includes coremaking, heat treatment, machining and many others.

Applied Casting Solutions

Mike Peach and Jacques Swanepoel will be on the ASK Chemicals stand. For further details

TEL: 011 922 1600 or visit www.chemsystems.co.za

ASK Chemicals Hall 12 Stand A22

Developer and manufacturer of organic and inorganic high-performance binder systems, coating systems, riser and filter systems, foundry aids and additives for the production process of cast parts.

Ceramic & Alloy Specialists

Wouter Retief, Brian Clough and Janley Kotze will attend. For further details TEL: 011 894 3039 or visit www.ceramicalloy.co.za

Elkem Foundry Supplies Hall 13: Stand C40

Producer of Ferro Silicon Magnesium and Inoculants for the ferrous foundry industry.

Hoesch Metallurgie Hall 13: Stand E60

Manufactures a wide range of master alloys, grain refiners, metals, alloys, ceramics and our well-known Dursalit fluxes.

IMF (Impianti Macchine Fonderia) Hall 15: Stand F16

Manufacturers and designers of chemically bonded moulding systems including turnkey moulding plants and core shooting machines, shotblasting and shotpeening machines.

Foundry Automation and Carlo Banfi are part of the group.

Mammut-Wetro Schmelztiegelwerk Hall 10: Stand H60

Manufacturers of crucibles and related hot metal products.

Newform Foundry Products Hall 10: Stand F77

Supplier of Mica slip-plane for re-lining of induction coil furnaces, Mica and other thermal and electrical insulation products.

Progelta S.r.l. Hall 16: Stand H12-1

Grey and ductile iron foundry molten metal treatment and automation systems.

Schafer Chemische Fabrik Hall 12: Stand B43

Manufacturers of fluxes, and non-ferrous molten metal treatment products.

Selee Corporation Hall 12: Stand B44

Design and manufactures porous technical ceramics and metals for a wide range of industrial applications.

StrikoWestofen GmbH Hall 11: Stand D38

Designers and manufacturers of melting, holding and casting furnaces for the aluminium, magnesium and zinc industries.

Cerefco

Scott Melville will be on the Inductotherm Group stand. For further details TEL: 011 845 3263 or visit www.cerefco.co.za

Inductotherm Group Hall 10 Stand D42

Inductotherm Group is a fully global manufacturing group of companies providing value to the metals and materials industry through production machinery, process knowledge, engineering excellence, and advanced technology. Product brand names include Inductotherm, Radyne, Inductoheat, Consarc, Thermatool, Inductoscan, Inductoforge, IRoss, Alpha and Banyard.

Inductotherm Group will be highlighting products such as the Inductotherm automated robotic melt shop system, Inductoscan induction scanner and the Inductoforge modular induction forge heater.

Durrans RMS

Mike Robinson and Reiner van Rooyen will attend. For further details TEL: 011 917 0702 or visit www.durransrms.co.za

James Durrans & Sons Ltd Hall 12 Stand A40

Manufacturers of refractory coatings suitable for non ferrous, ferrous and steel casting industries as well as carbon based products for a wide range of markets. Such products include natural and synthetic graphites, recarburisers, ground coal and clay blended materials. An additional part of the product range includes graphite shapes and components.

Endeco Omega Foundry Machinery

Rui Dias and Victor Dias will attend. For further details TEL: 011 907 1785 or visit www.endeco-omega.co.za

Omega Foundry Machinery Hall 15 Stand D28

The company designs and manufactures equipment for sand mixing from 1 to 100 tons per hour (pivotal, articulated and mobile models); mould handling – fast-loop systems and carousels to accommodate mould sizes from 800 x 600 to 3000 x 2000mm; reclamation – mechanical attrition units from 1 to 20 tons per hour, thermal from 1 to 3 tons per hour and secondary attrition units from 3 to 10 tons per hour; core making – 2.5 to 100 litre jobbing and semi-automatic core shooters for gas hardened and heat-cured processes, as well as turnkey project services.

Endress+Hauser Hall 05 Stand B19

For further details TEL: 011 262 8000 or visit www.za.endress.com

Measurement instrumentation, services and solutions for industrial process engineering.

The company provides sensors, instruments, systems and services for level, flow, pressure and temperature measurement as well as analytics and data acquisition. The company supports customers with automation engineering, logistics and IT services and solutions. The products set standards in quality and technology.

ExOne GmbH Hall 15 Stand C29

For further details visit www.exone.com

ExOne™ is a provider of industrial sand 3D printing machines and production service.

Foseco South Africa

Enno Krueger, Warren Zandberg, Kobus van der Berg and Hayden Johns will be on the stand. For further details TEL: 011 903 9500 or visit www.foseco.com or alternatively www.foseco-at-gifa.com

Foseco Foundry Division Hall 12 Stand A01

Visit the stand to see more about filtration technology for iron and steel foundries, pouring temperature measurement for cast iron, dynamic inoculation for iron and steel foundries, ITACATM (a thermal analysis system for iron foundries), melt shop refractories for iron and steel foundries, coatings for iron and steel foundries, centrifugally cast iron cylinder liners for iron and aluminium foundries, binders for iron, steel and aluminium foundries, metal treatment for aluminium foundries and metal transport for aluminium foundries.

GFE-MIR Alloys & Minerals Hall 13 Stand A31

Russell Symons, Jaco Janse van Rensburg and Cynthia Strydom will attend.

The GfE-MIR Group is specialises in the marketing of alloys and associated products for the steel, foundry and light metals industries.

Helium Process Technologies

Contact Rhynhardt Huygen on Mobile: +27 82 552 9673

Magaldi Industrie S.r.l. Hall 16 Stand D24

Manufacturers of hot bulk material handling and dry bottom ash extraction equipment for several industrial sectors including power and coal fired boilers, cement, lime and gypsum, foundries, steel mills and other metallurgic industries.

IMP Scientific and Precision

Donald Osmond will be on the Bruker stand on Wednesday 17 June 2015. For further details TEL: 011 916 5000 or visit www.imp.co.za

Bruker GmbH Hall 11 Stand G11

A manufacturer of scientific instruments for molecular and materials research, as well as for industrial and applied analysis.

Insimbi Alloys

Dudley de Beer, Samantha Le Roux and Fred Botha will attend and you can contact them via the South African National Pavilion or visit their suppliers. For further details TEL: 011 902 6930 or visit www.insimbi-alloys.co.za

EFP/Allied Metals Hall 13 Stand C55

A global supplier of high-purity, low carbon steel and stainless steel melt stock.

Frenzelit Werke GmbH Hall 9 Stand A60

A manufacturer and supplier of gaskets, technical textiles, expansion joints, insulation and new materials.

Larpen Metallurgical Service Hall 11 Stand B04

Supplier of graphite products and carbon additives.

Metal Filtration Ltd. Hall 15 Stand H28-01

Manufacturer and supplier of technical ceramics, refractories, textiles and insulation.

Refratechnik Casting GmbH Hall 5 Stand F08

Manufacturer of refractory bricks, prefabricated material, monolithic refractories, tundish and ladle cover material and synthetic slag.

Scottish Chemical Industries Hall 11 Stand B10

Manufacturer and exporter of hexachloroethane, degasers, grain refiners, foundry fluxes, coatings, (Ti & Sr) modalloys, (Mn, Cu, Fe) adal tablets, AITi5B1 coils, boron hardener, magnesium, ingots, fast melting silicon, ceramic foam filters, crucibles and castables.

SEEIF Ceramic, a.s. Hall 12 Stand A29

Producer of shaped and monolithic refractories.

SNAM Alloys Pvt. Ltd. Hall 13 Stand C39

Manufacturer of ferro silicon, ferro silicon magnesium and ferro silicon based inoculants.

WIRE d.o.o. Hall 13 Stand C31

A cored wire producer.

Krier Africa

John Williams will attend and will be on the Disa Industries stand. For further details TEL: 011 616 0844 or visit www.kriergroup.co.za

Disa Industries A/S Hall 16 Stand E10

Disa’s moulding product portfolio comprises vertical, match plate and horizontal green sand moulding systems. In addition to the moulding technology platforms, the company supplies equipment for sand plants, conveyor systems, cooling drums, cleaning solutions, CIM modules and core machine plants. They also supply equipment relating to surface preparation/shotblast technology under the Wheelabrator brand name.

LTM Mulondo Holdings

Hardus Visagie, Francois Oosthuysen and Zane Swanepoel will be attending and you can find them on the Vesuvius/Foseco stand Hall 5 Stand D19. For further details TEL: 016 450 4332/4021 or visit www.ltmholdings.com

Mineral-Loy

Hans Joubert and Phillip Steenkamp will attend. For further details TEL: 011 802 4050 or visit www.mineral-loy.co.za

FerroPem Foundry Products Hall 13 Stand A59

Manufacturer of inoculation and nodularization techniques to use within the iron foundry industry.

KBM Affilips Hall 13 Stand B60

Manufacturer and marketer of master alloys.

Mondeco Solutions

Peter Petersen will attend. For further details TEL: 079 448 1277 or visit www.mondeco.co.za

Can-Eng Furnaces International Ltd Hall 10 Stand G41

Designer and manufacturer of industrial heat treating equipment.

Clansman Dynamics Ltd Hall 16 Stand C24

Provides specialised handling solutions in the area after the mould is poured. Product range includes automatic degating, handling and grinding manipulators, hammers and wedges for casting separation, gating cutters.

EKW Refractories Hall 10 Stand H21

Manufactures a comprehensive portfolio of refractory materials including castables, neutral, basic and acidic semi-plastic as well as dry-vibration mixes, all the way to specific materials for a full range of repair and spray work.

IBO Anlagenbau GmbH Hall 10 Stand D66

Designs and manufactures extraction hoods for induction furnaces.

Omega Foundry Machinery Ltd. Hall 15 Stand D28

See Endeco-Omega Foundry Machinery for details.

Otto Junker GmbH Hall 10 Stand E18

The product range embraces melting, casting, heating and heat treating equipment for the aluminium and copper industries, as well as melting and casting equipment for iron and steel foundries.

Pangborn Group Hall 16 Stand E33

Designs, manufactures and services wheel blast, air blast, shot peening and other surface preparation machines, blast machine components such as blast wheels, parts and related products to serve a range of industries.

SiiF Hall 16 Stand A09

Manufactures foundry finishing equipment for iron, aluminium and steel castings such as fettling, trimming and decoring.

Simpson Technologies Hall 15 Stand D02

Specialises in foundry and process mixing technologies including green sand moulding sand preparation, control and reclamation comprising moulding sand coolers, batch and continuous mullers, on-line process controls, sand reclamation, sand laboratory instrumentation and equipment, shell core machines, pneumatic bond transporters and system automation.

Vibroprocess S.r.l. Hall 16 Stand H12-04

Designs and manufactures vibratory equipment such as shake outs.

Morgan Advanced Materials Hall 11 Stand A04

Eddie Short will be on the stand. For further details TEL: 011 815 6820 or visit www.morganthermalceramics.com

Morgan Advanced Materials manufactures a wide range of specialist products specifically developed to improve the performance, reliability and efficiency of industrial furnaces and other industrial processes. The range includes high temperature insulating fibre including Superwool low-biopersistent fibre and microporous WDS technology to the insulating firebrick range.

Morgan also has a comprehensive range of tubes and Alsint 99.7 laboratory porcelain equipment for applications up to 2000 °C.

Saveway GmbH & Co. KG Hall 10 Stand D41

The company is engaged in the production, installation and worldwide sales and distribution of measuring technology for melting plants in the foundry industry, the steel industry, metallurgical industry as well as the glass industry. Visit www.saveway-germany.de

Sidermet

Paul Mitchell will be attending. For further details TEL: 011 892 3002 or visit www.sidermet.co.za

Agellis Group AB Hall 5 Stand B29

Molten metal measurement technology for the ferrous and nonferrous metals industries including furnace bath level measurement and hot heel management systems, furnace/smelter material profile measurement systems, TSL furnace metal level tracking systems, furnace slag detection systems, ladle fill level systems, ladle slag detection systems, tundish real metal level and drain level systems, mould level measurement systems and thermographic ladle monitoring systems.

Arun Technology Metalscan Ltd. Hall 15 Stand H16-02

Design and manufacture a range of ‘PolySpek’ desktop and ‘A’ Series portable spectrometers designed specifically for metals analysis.

Phoenixtm Hall 9 Stand C59

Innovative temperature profiling monitoring systems with thermocouples, probes and data loggers.

Sidermes S.p.A. Hall 03 Stand C09

A manufacturer and supplier of measuring probes connectable with PC or PLC.

Sigma Wear Parts

Andrew Ryan and Eddie Ryan will be attending. For further details TEL: 011 823 4443 or visit www.sigmateamsa.com

Kuhmichel Abrasives GMBH Hall 16 Stand C40

Sigma Wear Parts stainless steel abrasive products will be displayed on the Kuhmichel Abrasives GMBH stand. Kuhmichel Abrasives are the biggest abrasive supplier in Europe.

Sigma Wear Parts are manufacturers of stainless steel abrasives as well as low carbon steel shot, ferro silicon powders both milled and atomised and have a foundry producing castings in stainless steel, chrome alloys, steel, SG iron and various grades of aluminium.

SI Group HA

Gordon McNeilage and Colleen Boyce will attend. For further details TEL: 011 389 8200 or visit www.siigroup.com

Hüttenes-Albertus Chemische Werke Hall 12 Stand C50

A manufacturer of chemical products for the foundry industry for use in all established coremaking and mouldmaking processes. The company’s products include inorganic binder systems, cold-boxes, hot-boxes, no-bakes, adhesives, shell moulding process products, resole-co2, coatings, special sands, parting agents, and release agents.

Silca South Africa

Alexander Saam will be on the stand. For further details TEL: 011 454 4702, Cell 060 972 7505, email alexander.saam@enthalpie-sa.com or visit www.silca-online.com

Calsitherm Silikatbaustoffe GmbH Halle 09 Stand F40

A manufacturer of high performance, asbestos free calcium silicates, in a density range of 200 to 1100 kg/m³. The products are used worldwide in industrial plants like petrochemical, cement and power generation, domestic and commercial fire protection solutions, metallurgical and process industries and other engineering industries.

Spectro Analytical Instruments

Marie Jusling and John Taylor will attend. For further details TEL: 011 979 4241 or visit www.spectro.com

Spectro Analytical Instruments Hall 11 Stand H21

Designers, manufacturers and suppliers of analytical instruments for optical emission and x-ray fluorescence spectrometry.

HA Inorganic Binder (IOB) System seminar and workshop at GIFA 2015

Hüttenes-Albertus Chemische Werke has announced that the company will hold a one day seminar on the 17th June 2015 during the GIFA 2015 exhibition. The seminar will take place from 9:30 AM to 15:00 PM in Hall R, which you get to via Entrance CCD East (in close proximity to Hall 14 and 15).

The seminar will be hosted by Dr.-Ing. Ion Alexandru Bacanu with the support of

Ralf Boehm, Christian Fourberg, Klaus Löchte, Dr. Christian Lustig, Martin Vorrath and Timm Ziehm.

Topics to be covered include:

- Basics of the HA IOB process

- Environmental aspects

- The inorganic process generated change

- Equipment (core shooter, core box)

- Related auxiliary products (parting agents, glues, coatings) development trends

If you would like to attend contact Colleen Boyce of SI Group SA on TEL: 011 389 8200